The stringing conveyor is designed for stringing fish on a rod (skewer). Further, these bars going to frame and smoke oven.

The smoke produced by the furnace under the desired number of workstations (popular are 14 or 16). The workplace is equipped with a cassette, where the fish is placed, the rod is inserted, the cassette opens and the rod with the fish goes to the frame. This solution allows you to speed up the process of stringing fish 2-3 times.

There are compact tables stringing on 2 jobs.

-

-

The stringing table is intended for stringing fish on a rod (skewer). Further, these bars going to frame and smoke oven.

The workplace is equipped with a cassette, where the fish are placed, the rod is inserted, the cassette opens and the rod with the fish goes to the frame. This solution allows you to speed up the process of tattooing fish 2-3 times.

-

This machine is designed for cutting heads in sprat semi-finished product. The frame with bars (skewers) is placed on the machine for cutting heads and two knives cut off the head.

In addition, we can equip with a comb and a remote conveyor. The comb accelerates the process of removing the heads from the bar. The remote conveyor allows you to directly feed the semi-finished product to the line for further processing.Technical parameters:

- Conveyor speed: 0.2 m/s

- МPower of conveyor reducer motor: 0.12 kW

- Speed of rotation of disks with knives: 2820 rpm

- The power of the motors of the cutting discs: 0.75 kW each (2 or 4 PCs.)

- Capacity (finished product): up to 45 kg or 15 frames

- Total power consumption

- heads and tails: 3.12 kW

- head: of 1.62 kW

- Size

- length: 2525 mm

- width: 1300 mm

- height: 1030 mm

-

This machine is designed for cutting heads in sprat semi-finished product. The frame with bars (skewers) is placed on the machine for cutting heads and two knives cut off the head. Thanks to the remote conveyor, the semi-finished product immediately goes to the packaging line, saving time and labor.

Additionally, we can equip the comb. The comb accelerates the process of removing the heads from the bar.Technical parameters:

- Conveyor speed:0,2 m/с

- Power of conveyor reducer motor: 0.12 kW

- Speed of rotation of disks with knives:2820 rpm

- The power of the motors of the cutting discs: 0.75 kW each (2 or 4 PCs.)

- Capacity (finished product): up to 45 kg or 15 frames

- Total power consumption

- heads and tails: 3.12 kW

- head: of 1.62 kW

- Size

- length: 2525 mm

- width: 1300 mm

- height: 1030 mm

-

This machine is designed for cutting the heads and tail of the sprat semi-finished product. The frame with bars (skewers) is placed on the machine for cutting heads and two knives cut off the head,and the other two knives cut off the tail. In addition, we can equip with a comb and a remote conveyor. The comb accelerates the process of removing the heads from the bar. The remote conveyor allows you to directly feed the semi-finished product to the line for further processing.

Technical parameters:

- Conveyor speed: 0.2 m / s

- The power of the motors of the cutting discs0.12 kW

- Speed of rotation of disks with knives: 2820 rpm.

- The power of the motors of the cutting discs0.75 kW each (2 or 4 PCs.)

- Capacity (finished product): up to 45 kg or 15 frames

- Total power consumption

- heads and tails: 3.12 kW

- head: of 1.62 kW

- Size

- length: 2525 mm

- width: 1300 mm

- height: 1030 mm

-

This machine is designed for cutting the heads and tail of the sprat semi-finished product. The frame with bars (skewers) is placed on the machine for cutting heads and two knives cut off the head,and the other two knives cut off the tail. Thanks to the remote conveyor, the semi-finished product immediately goes to the packaging line, saving time and labor.

In addition, we can equip the comb, which speeds up the process of removing the heads from the bar.Technical parameters:

- Conveyor speed: 0.2 m/s

- Power of conveyor motor-reducer: 0.12 kW

- Speed of rotation of disks with knives: 2820 rpm.

- The power of the motors of the cutting discs: 0.75 kW each (2 or 4 PCs.)

- Productivity (finished products): up to 45 kg or 15 frames

- Total power consumption

- heads and tails: 3.12 kW

- head: of 1.62 kW

- Size

- length: 2525 mm

- width: 1300 mm

- height: 1030 mm

-

The Smoking framework is used for fastening of rods (skewers) with fish. Further, this frame to put in the cart and carried in the smoke oven. After the Smoking oven carts are removed from the frame and go to the sprat thug. The Smoking frames are manufactured to the required dimensions of black metal/stainless steel trolleys.

The Smoking framework is used for fastening of rods (skewers) with fish. Further, this frame to put in the cart and carried in the smoke oven. After the Smoking oven carts are removed from the frame and go to the sprat thug. The Smoking frames are manufactured to the required dimensions of black metal/stainless steel trolleys. -

The Smoking framework is used for fastening of rods (skewers) with fish. Further, this frame to put in the cart and carried in the smoke oven. After the Smoking oven carts are removed from the frame and go to the sprat thug. The Smoking frames are manufactured to the required dimensions of black metal/stainless steel trolleys.

The Smoking framework is used for fastening of rods (skewers) with fish. Further, this frame to put in the cart and carried in the smoke oven. After the Smoking oven carts are removed from the frame and go to the sprat thug. The Smoking frames are manufactured to the required dimensions of black metal/stainless steel trolleys. -

The cart for frames is intended for collecting, storage and transportation of frames in shop.

The cart for frames is intended for collecting, storage and transportation of frames in shop. -

Trolley for rods (skewers) is designed for collection, storage and transportation.

Trolley for rods (skewers) is designed for collection, storage and transportation. -

The cassette is designed for stringing (tattoos) of fish on a rod. Cassettes are made of different widths and for different amounts of fish. The cassette is secured on the workspace (line nanosci or table nanski). We offer different lengths: from 670 mm (standard) to 1 meter and for different amounts of fish. Cassettes are made of strong food-grade plastic.

The cassette is designed for stringing (tattoos) of fish on a rod. Cassettes are made of different widths and for different amounts of fish. The cassette is secured on the workspace (line nanosci or table nanski). We offer different lengths: from 670 mm (standard) to 1 meter and for different amounts of fish. Cassettes are made of strong food-grade plastic. -

The rod (skewer) is intended for pricking of fish on it and further Smoking. The rod is made of black metal and stainless steel. We offer different lengths: from 670 mm and a diameter of 4 mm (standard) to 1 meter.

The rod (skewer) is intended for pricking of fish on it and further Smoking. The rod is made of black metal and stainless steel. We offer different lengths: from 670 mm and a diameter of 4 mm (standard) to 1 meter. -

-

This equipment is intended for cleaning and washing of Smoking rods from the stuck remains of fish after Smoking. The rod are loaded into the bath with a degreasing detergent solution on the hanging loops of the drive chains. After starting the machine, the rods are rolled and thus RUB against each other and cleaned.

Technical parameters:

- Max loading weight: 30 kg

- Washing chain drive-gear motor

- power: 0.37 kW

- the Rev: 35 rpm.

- Overall dimensions

- length: 860 mm

- width: 570 mm

- height: 960 mm

-

This device is installed on the workplace and accelerates the process of laying fish, such as sprat, in a glass can (vertically) 2-3 times .

The worker puts the fish in a special container and then the laid fish gets into the jar. This relieves the workers of shoving the carcass of each fish in a can. -

The Smoking-cooking chamber is made of acid-resistant steel. Depending on the customer's requirements, the chamber can be extended (from two trolleys and more).

Between the inner and outer walls placed thermal insulation of pressed mineral cotton. Door insulation is made of polyurethane foam. A single-speed motor is mounted on the roof of the chamber, which drives the fan, which causes, depending on the type of process, air circulation. On the roof are fixed also fresh air valves, smoke and exhaust valves together with pneumatic servomotors.

In addition, the chamber is equipped with an electrical system, water and pneumatic systems. The connection of the electrical, water and air system is located on the so-called island, equipped with electrovalves of air, water and air conditioning unit. The power of the camera can be oil, steam or electric.

This equipment is automatic and does not require manual control, but only periodic inspection by the service Department.Inside the chamber are placed:

- fan;

- inflatable channels;

- heating device;

- suspended ceiling;

- tar removal channels;

The doors are mounted on three curtains, equipped with a handle and silicone seal.

Control cabinet

The control Cabinet with the command controller is made of acid-resistant stainless steel. The Cabinet is equipped with an automatic control system to control the operation of the entire Smoking and cooking system.

The most important element of the equipment is a microprocessor command controller, which is used to program all parameters of technical processing and control the operation of the entire system of Executive devices. -

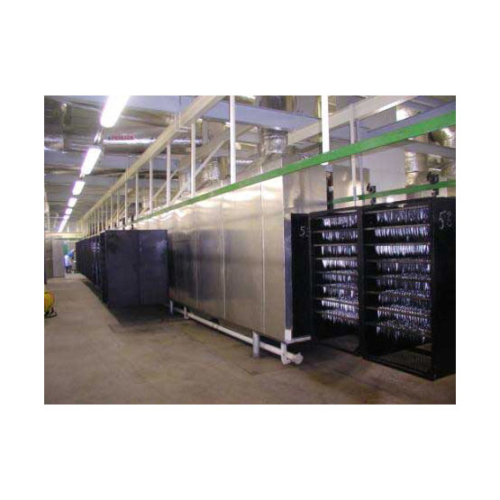

BP1872 two-Ton smoke oven is designed for hot Smoking of small fish (sprat, herring, capelin, etc.) and is part of the Smoking unit. The furnace consists of two symmetrical halves working independently. Each half is divided into 16 sections, divided into three zones: drying, Smoking and cooling. Containers with products are moved in sections cyclically.smoke oven

Technical parameters:

- The productivity of the furnace for the finished product: of 0.8 - 1.0 tons/h

- Consumption

- smoke's: 1000 - 1200 m³/ч

- heat: 360000 - 500000 kcal/h

- pair (at p = 0.4...0.5 MB/m2): 1000 kg/h

- Absorbability

- hot air: 20000 - 22000 m³/h

- smoke-air mixture: 10000 - 12000 m³/h

- Gas consumption: 50 m3/h

- The number of containers in tunnels:32

- Supply of containers to the tunnelmanual

- The dimensions of the furnace

- length: 1,3 m

- width: 3,0 m

- height: 5,44 m (макс.)

-

This equipment is a compact and professional dryer for food products. The series is represented by two models: 40 and 72 pallets. The 5.1 kW heating system achieves a drying temperature of 65 °C. an optional 3.4 kW heating system is available for drying more delicate crops (e.g. medicinal herbs) . Like all dryers, this model has a modular design and can be expanded in the future through additional modules.

This equipment is a compact and professional dryer for food products. The series is represented by two models: 40 and 72 pallets. The 5.1 kW heating system achieves a drying temperature of 65 °C. an optional 3.4 kW heating system is available for drying more delicate crops (e.g. medicinal herbs) . Like all dryers, this model has a modular design and can be expanded in the future through additional modules. -

This equipment is intended for washing of Smoking tunnels and keeping them in working condition.

This equipment is intended for washing of Smoking tunnels and keeping them in working condition. -

Carts for Smoking stoves. We also offer: frames, bars, mesh pallets.

Carts for Smoking stoves. We also offer: frames, bars, mesh pallets. -

The smoke generator is the equipment in which as a result of decay of wood smoke of Smoking is formed. The type of wood used for Smoking greatly affects the color of the product. For example: oak and alder wood gives a Golden-yellow and brown color, respectively.

The smoke generator is a hermetic equipment in which as a result of processing of a dry shaving with humidity of 12 - 20% at a temperature of 360 °C smoky smoke is made.

The smoke has a temperature no higher than 54 °C at the outlet of the smoke generator and is dry.The smoke generator consists из:

- tube tank;

- the stirrer motor, which drives the dz-100 smoke generator stirrer;

- servomotor, which drives the stirrer of the smoke generator;

- drive motor agitator smoke generator DZ-100 or for cameras one and two-telescopic drives the agitator smoke generator DZM-50;

- the channel with a steam heater and a scraper;

- smoke temperature sensor;

- water sprinkler;

- dividing pipe;

- inflatable air motor with filters;

- pneumatic control valve;

- transformer's

- smoke generator warmers (24 V);

- flue pipe;

- furnace with a drawer.

The smoke generator is manufactured with stainless steel.

-

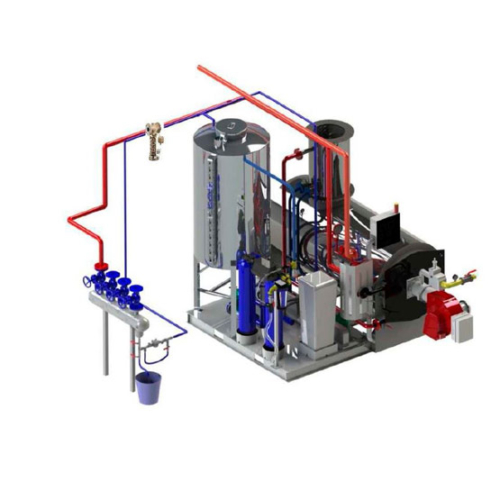

This equipment is designed for steam production.

Technical parameters:

- Steam capacity: 1000 kg / hour (600.000 Kcal / hour)

- Power: 700kw

- PERFORMANCE: 92%

- The water temperature at the inlet: from 1 to 90 °C

- Type of fuel: natural gas

- Gas pressure: average (300 mbar)*

- Vapor pressure (regulates): 14 бар **

- Steam temperature: 198 °С (maximum)

- Gas consumption (max): 72 m3 / h***

- Noise level: 75dB

- Габариты без горелки (ДхШхВ), мм: 2300 x 1530 x 2190 ****

- * - The ideal is the gas pressure at the inlet of the steam generator burner within 200 -300 mbar. At a lower pressure, the gas ramp must be additionally equipped with auxiliary equipment .

- ** - The steam pressure can be adjusted from 1.0 to 14.0 bar according to the process requirements .

- *** - The theoretical maximum fuel consumption during continuous operation of the steam generator for an hour at maximum performance is indicated. The actual consumption is 40-70% of the specified volume, depending on the intensity of steam consumption.

- **** - The manufacturer reserves the right to make changes in the overall dimensions of the equipment due to production needs and due to technical improvement.

-

USEDThe line on low (tattoos) fish is intended for stringing fish on a rod (skewer/skewer) and its further processing (usually Smoking). There are 14 workstations on the line and each is equipped with a cassette with a pedal. There are several lines of different configuration.

USEDThe line on low (tattoos) fish is intended for stringing fish on a rod (skewer/skewer) and its further processing (usually Smoking). There are 14 workstations on the line and each is equipped with a cassette with a pedal. There are several lines of different configuration. -

USEDAutomatic cutting line (tattoos ) of fish.

USEDAutomatic cutting line (tattoos ) of fish.