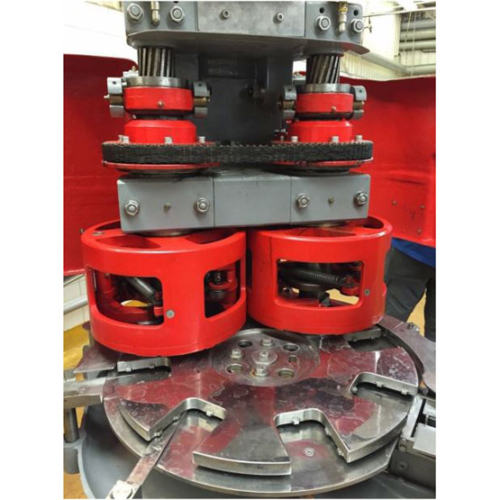

This equipment is equipped with a vacuum pump and is used to create a vacuum and the subsequent seaming of glass containers (cans and bottles) covers “Twist-off”. Creation of vacuum and seaming takes place in a special vacuum chamber.

The installation is semi-automatic. The container is installed and removed manually. The vacuum level is controlled by the operator using a pressure gauge mounted on the lid of the vacuum chamber. Seaming of containers on the installation is carried out by one operator.

Specifications of BP2450:

- Productivity PCs / hour:1200 – 1500

- Tube diameter, mm:30 – 85

- Bottle height, mm:50 – 180

- Bottle diameter, mm:30 – 80

- Power supply voltage: 220V / 50 Hz

- Limit residual pressure, MPa:-0,08

- Installed capacity: 1.3 kW

- Air consumption, m3/min.: 0,3

- Overall dimensions (LxWxH) mm:1000 x 760 x 1520

- Weight, kg:260

- Maintenance staff, people.: 1

Specifications BP2450-2:

- Productivity, PCs / hour:1200 – 1500

- Tube diameter, mm:85 – 110

- Bottle height, mm:120 – 250

- Bottle diameter, mm:80 – 150

- Power supply voltage: 220V / 50 Hz

- Limit residual pressure, MPa:-0,08

- Installed capacity: 1.3 kW

- Air consumption, m3/min.:0,3

- Overall dimensions (LxWxH) mm:1000 x 760 x 1520

- Weight, kg:260

- Оblogiausiu the staff people.:1