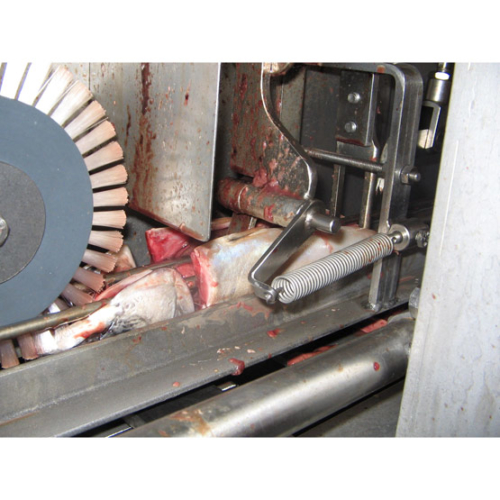

The evisceration machine is designed to gut an entire fish. Suitable for trout, mackerel, herring, perch and other similar fish.

- Productivity, PCs/min.: to 50

- Fish size, g:150 - 1200

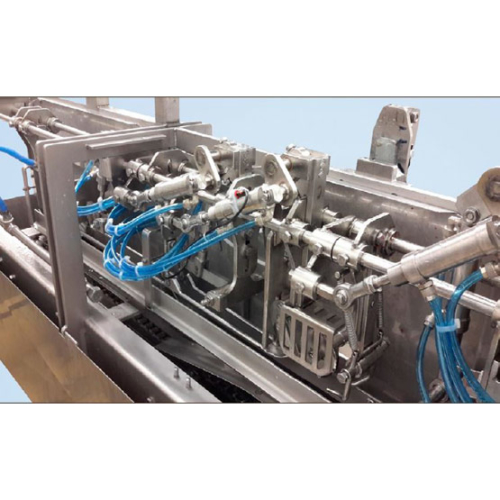

The machine has a reliable design, it is easy to operate and easy to maintain (maintenance costs are minimal).

The equipment is produced according to the customer's specifications (dimensions of carcasses that need to be gutted) according to all EU standards. In the process of gutting fish damaged less than 0.5%.

The operator's workplace is ergonomic and conveniently located, and safety is at the highest level.

Technical parameters:

- Power: 380V / 50Hz

- Water consumption, liters per hour:500

- Compressed air: 6 bar

- Air compressor: 2 kW (minimum value)

- Weight, kg:350