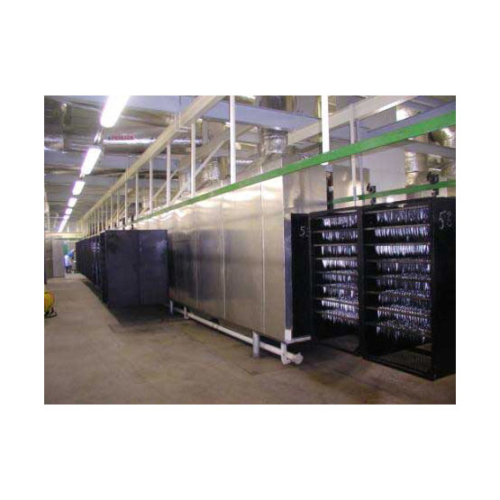

The Smoking-cooking chamber is made of acid-resistant steel. Depending on the customer's requirements, the chamber can be extended (from two trolleys and more).

Between the inner and outer walls placed thermal insulation of pressed mineral cotton. Door insulation is made of polyurethane foam. A single-speed motor is mounted on the roof of the chamber, which drives the fan, which causes, depending on the type of process, air circulation. On the roof are fixed also fresh air valves, smoke and exhaust valves together with pneumatic servomotors.

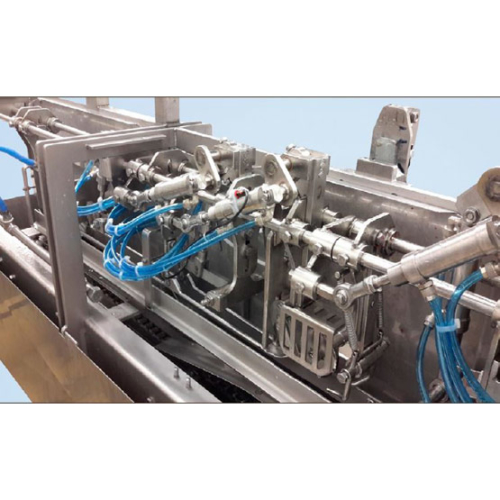

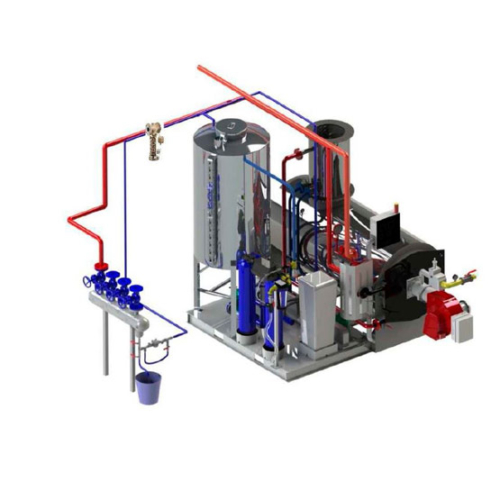

In addition, the chamber is equipped with an electrical system, water and pneumatic systems. The connection of the electrical, water and air system is located on the so-called island, equipped with electrovalves of air, water and air conditioning unit. The power of the camera can be oil, steam or electric.

This equipment is automatic and does not require manual control, but only periodic inspection by the service Department.

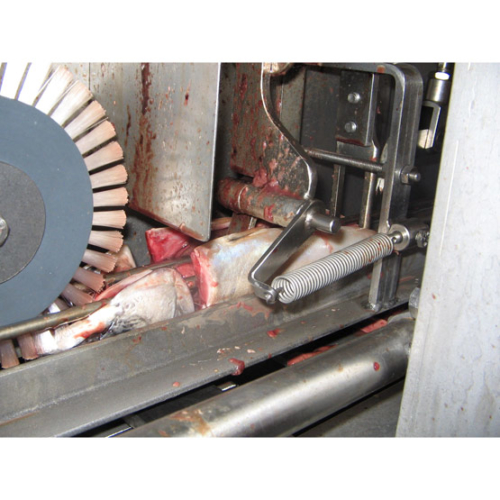

Inside the chamber are placed:

- fan;

- inflatable channels;

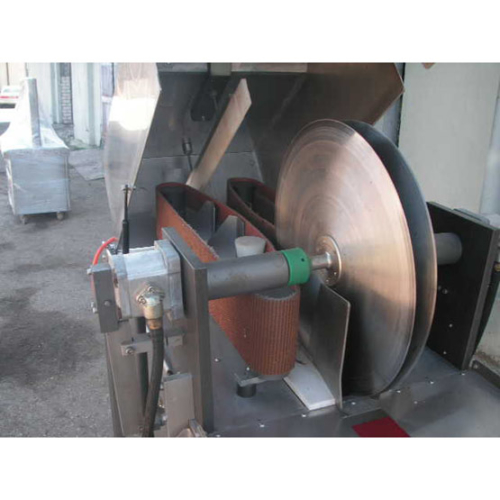

- heating device;

- suspended ceiling;

- tar removal channels;

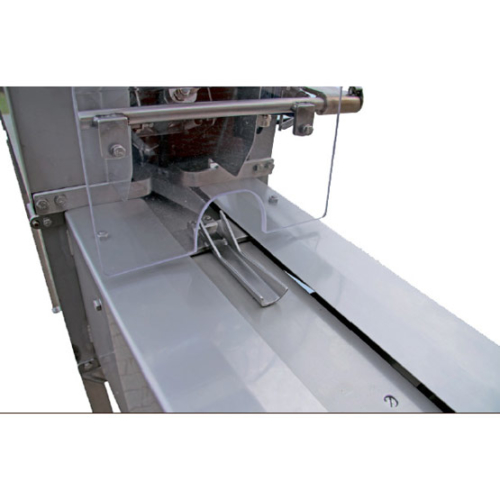

The doors are mounted on three curtains, equipped with a handle and silicone seal.

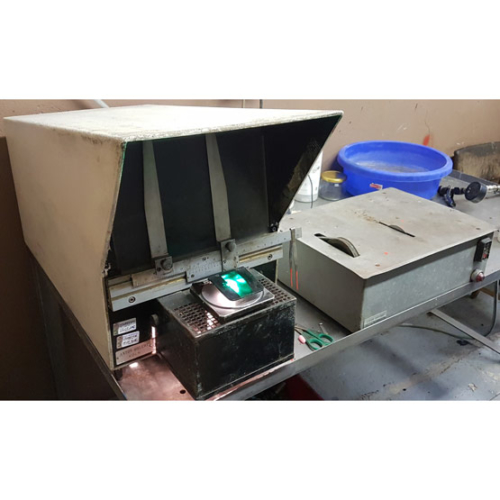

Control cabinet

The control Cabinet with the command controller is made of acid-resistant stainless steel. The Cabinet is equipped with an automatic control system to control the operation of the entire Smoking and cooking system.

The most important element of the equipment is a microprocessor command controller, which is used to program all parameters of technical processing and control the operation of the entire system of Executive devices.